It was on old 3.5" drives a long time ago, before anything fancy was ever built into the drives. It was in a seriously rough working environment anyway, so we saw a lot of failed drives. If strange experiments didn’t work to get the things working, mainly for lulz, the next option was to see if a sledge hammer would fix the problem. Funny thing… that never worked either.

- 0 Posts

- 82 Comments

I used to take failed drives while they were powered on and kinda snap them really with a fast twisting motion in an attempt to get the arm to move or get the platters spinning.

It never worked.

10·9 days ago

10·9 days agoDid you get bad sectors? Weird things can absolutely happen but having sectors marked as bad is on the exceptional side of weird.

8·9 days ago

8·9 days agoMaybe? Bad cables are a thing, so it’s something to be aware of. USB latency, in rare cases, can cause problems but not so much in this application.

I haven’t looked into the exact ways that bad sectors are detected, but it probably hasn’t changed too much over the years. Needless to say, info here is just approximate.

However, marking a sector as bad generally happens at the firmware/controller level. I am guessing that a write is quickly followed by a verification, and if the controller sees an error, it will just remap that particular sector. If HDDs use any kind of parity checks per sector, a write test may not be needed.

Tools like CHKDSK likely step through each sector manually and perform read tests, or just tells the controller to perform whatever test it does on each sector.

OS level interference or bad cables are unlikely to cause the controller to mark a sector as bad, is my point. Now, if bad data gets written to disk because of a bad cable, the controller shouldn’t care. It just sees data and writes data. (That would be rare as well, but possible.)

What you will see is latency. USB can be magnitudes slower than SATA. Buffers and wait states are causing this because of the speed differences. This latency isn’t going to cause physical problems though.

My overall point is that there are several independent software and firmware layers that need to be completely broken for a SATA drive to erroneously mark a sector as bad due to a slow conversion cable. Sure, it could happen and that is why we have software that can attempt to repair bad sectors.

27·20 days ago

27·20 days agoIt’s been around for a while. It’s the fluff and the parlor tricks that need to die. AI has never been magic and it’s still a long way off before it’s actually intelligent.

Thanks for the additional info as it gave me a little more clarity on what kind of undertaking this is. I know electronics, but I really didn’t know the specifics of controllers. It didn’t take me long to get caught up, TBH.

That sucks. Before I was finished reading your full comment, I was already thinking of a way to intercept the signal for calibration. It seems that is already quite common and not easily possible for you.

My next thought was to 3D scan and print out a modified shell with a bit more room for electronics. Based on your description, that sounds tricky as well.

Whelp! I am effectively useless here and was hoping I could’ve helped a little. Doing extensive modifications to things is something I really enjoy, too.

Hall effect sensors may be slightly temperature sensitive and if that is the case, that information would be in the sensors datasheet. (This wouldn’t be an issue on a hall effect counter where the sensor would be connected to a Schmitt trigger and the signal is either on or off.)

For a precision application like yours, there could be a few problems stacking up from a possible software issue combined with temperature drift.

If there are software issues, it could be as simple as a min/max issue with the buffer that stores the stick position. (It’s fairly easy to get rounding errors that stack up after a while.)

Obviously, I am spitballing some theories to why your calibration gets corrupted, so take them with a grain of salt. My limited experience with hall effect sensors has been that they are hyper-sensitve and I have usually had to code around any kind of drift or sporadic readings. Hell, anything that has a magnetic field (just about everything) can upset the readings on those things.

Gots any datasheets or specific part numbers for the hall effect sensors you are using? (I believe you listed some module types, but actual part numbers could change from module to module.)

81·1 month ago

81·1 month agoThat is a very peculiar rant.

6·1 month ago

6·1 month agoAll you gotta do is pull up the data from a trustworthy source… like Xtwitter or Facebook.

2 cans? In the microwave?

9·2 months ago

9·2 months agoNo, but seppuku is generally the proper next step.

This bubble is quite bubbly. There is an AI company for anything and everything now. The market is almost fully saturated with “AI” everything.

Just like the web bubble, all of the intsta-AI shops need to fail so the real tech can grow. AI is never going to go away, but most of the scam companies will fail in due time.

We might have one big consolidation, or several. The hype will die and the quick money will disappear. It’s the same story, every time. One the magic AI box stops shitting out dollar bills, we should be good.

13·3 months ago

13·3 months agoTime passes differently for other lower orbit satellites as well. They just adjust the time to take up the slack but it’s likely done at very high precision.

Honestly, it should be really easy to figure out. Take two sycronized high precision clocks, put one in orbit and keep one on earth and then subtract one time from another after a few days. (At that precision, you also need to take into account the time it takes to radio the signal back to earth as well.)

That has its own benefits, for sure. I have been known to use a press or even a toaster oven as well.

However, grilled cheese for me is similar to cooking an egg. It’s the purest form of cooking and it’s an art form that is easy to screw up.

The butter to bread ratio needs to be perfect and the bread needs a perfect toast in a pan. In rare cases I’ll use some good cheeses, but American cheese is the only one that truly works. Butter the pan, not the bread. Keep the sammich moving at all times while it cooks. Timing is paramount for the toast.

If that makes the grilled cheese any better, I really don’t know. There is, in measurable quantities, more love added to it, so by default, it’s better.

What do I do with the stuff thats in the can though? I could just pour it down the drain, I suppose.

It’s mostly just the froth making it look weird, I think.

However, like you said, it does look a little thin. It’s not my personal preference, but if it works for OP then I am happy too.

61·4 months ago

61·4 months agolovable

I get it. You are being a kind soul. However, that word might be misplaced.

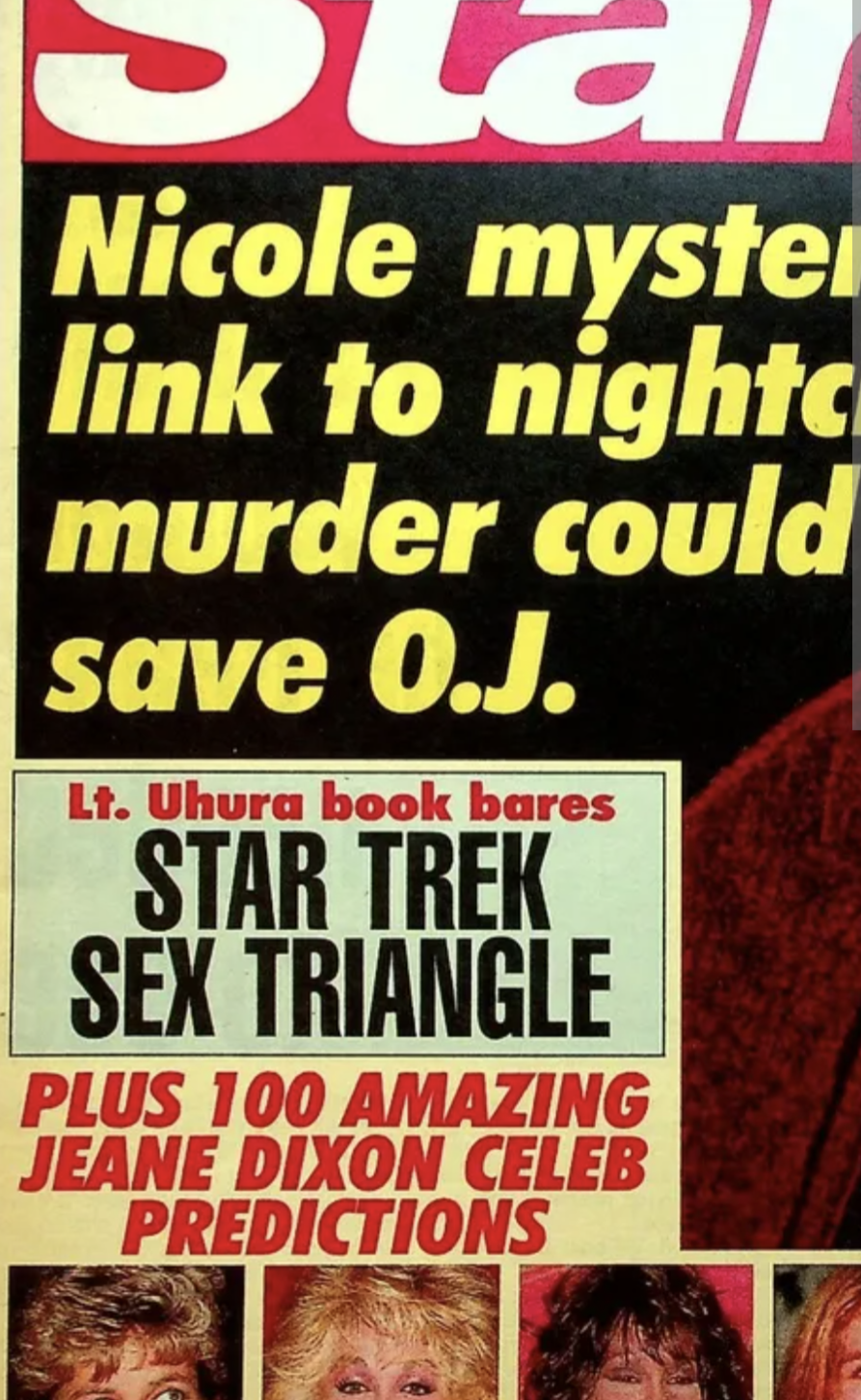

That is picture of an actual tabloid. It was in reference to a tabloid being about Star Trek, not about your actual question.

If any of these are an extension of our timeline, it’s likely that all newspapers are trash: https://memory-alpha.fandom.com/wiki/Newspaper

That’s the best I got unless you want to also discuss tabloids with Star Trek related stories…

I am going to need your 50 point summary of those obvious points in the longest form possible by this afternoon so I can be completely convinced that I have already made up my mind in the correct way. Thanks.