Might as well link to the original post on reddit, I don’t think Tom’s Hardware much value in their summary of it :)

Once you’ve finished this project, you’re only a hop and skip away from this 3D printed Machining Mill. He uses the 3d printed pieces as a mold for reinforced concrete, so that it’s heavy enough to resist the vibrations so that you can mill solid metal stock.

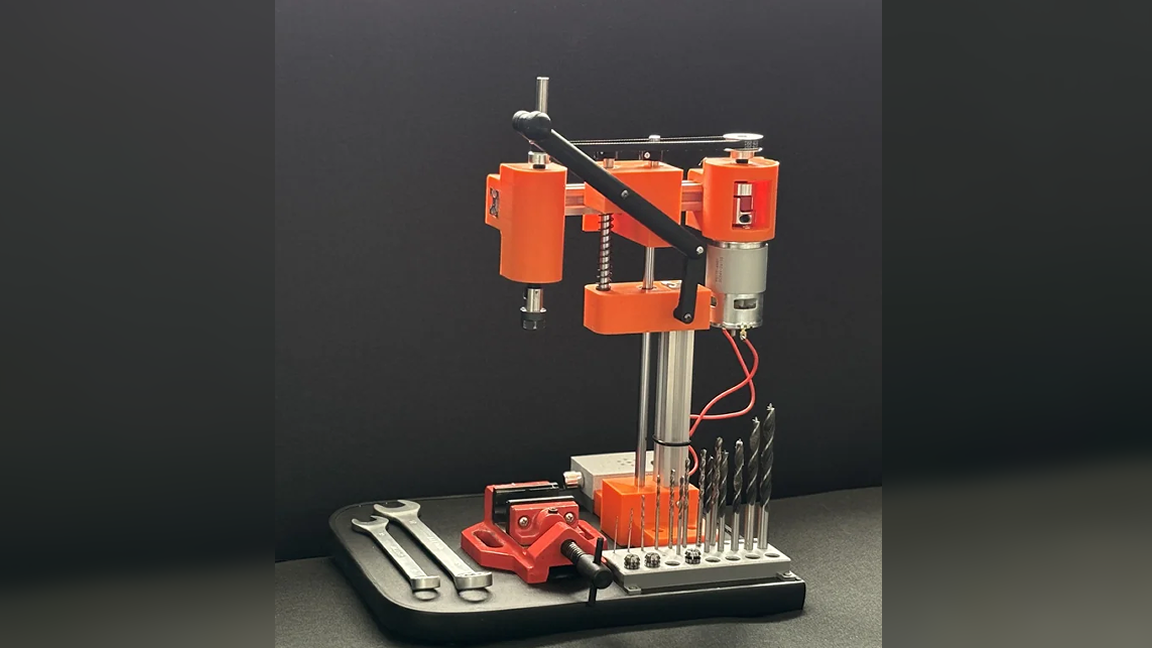

The single most impressive 3D printed DIY tool i’ve ever seen.

Has he released the files for this, yet? I just looked at the video again and it didn’t look like he had.

I do want to give it a try once he’s released them.

Not that I’m aware of, no

Also you might need a 400+ USD 3D Printer and the drill bits that can’t be printed.

Drilling through soft metals like aluminum and brass is possible with 2mm drills.

…yay?

I mean, I’m all for printing fun stuff just to see if it works. Just don’t make it sound like it’s a cheap solution for people who need a drill press…

It’s a 3d printing forum, most people here already have the 3d Printer for other uses. It’s an option for those people. Not someone who is starting from scratch.

Except it is entirely counterproductive and a project for a project’s sake.

There are stands that turn your regular drill into a “drill press”. 100x more rigid than whatever this is. And with drill presses, you can’t have deflection or it’ll ruin every part you make.

Alternatively, there are $50 drill presses too. Probably “worth the money”, but still more rigid than this.

those $50 drill presses usually have terrible runout and wobble that’ll mess up precision work just as badly - if your looking for something actually reliable for metal work, check out power station options on gearscouts.com to run a proper bench drill when you’re away from outlets.

Yeah, sure. But at the end of the day, whatever this project is, will work worse than the things I mentioned.

Well no, toms hardware is no 3d printer forum. I criticized their headline. Sorry if it came across another way.

It does kinda say this in the article.

I will add though, the main reason to use a drill press is precision, and it’s hard to imagine a 3D printed structure wouldn’t flex and warp during use.

it’s hard to imagine a 3D printed structure wouldn’t flex and warp during use.

Depends in the filament used. Would not use PLA for this stuff.

deleted by creator

It’s also very doable to get a for-real drill press for the price of making this.

i really like concrete guy’s version as well.

1st. You dou you. 2nd. Kudos for the design and ingenuity.

Now the buts:

I personally don’t agree with the concept of “I’m going to print this just to prove I can”, especially if it’s subpar.

I have so much h to print, for me and for others, that I see this as a waste of time an filament.

My own personal point of view.

I think it’s a good thing to try and explore how easy or hard it is to build this. It can all translate into building something entirely local, building things at higher quality for less money, or even building things in times of quarantine, trade embargoes, or just lower tech areas.